Calendering rolls for the textile industry

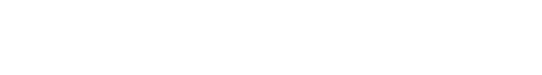

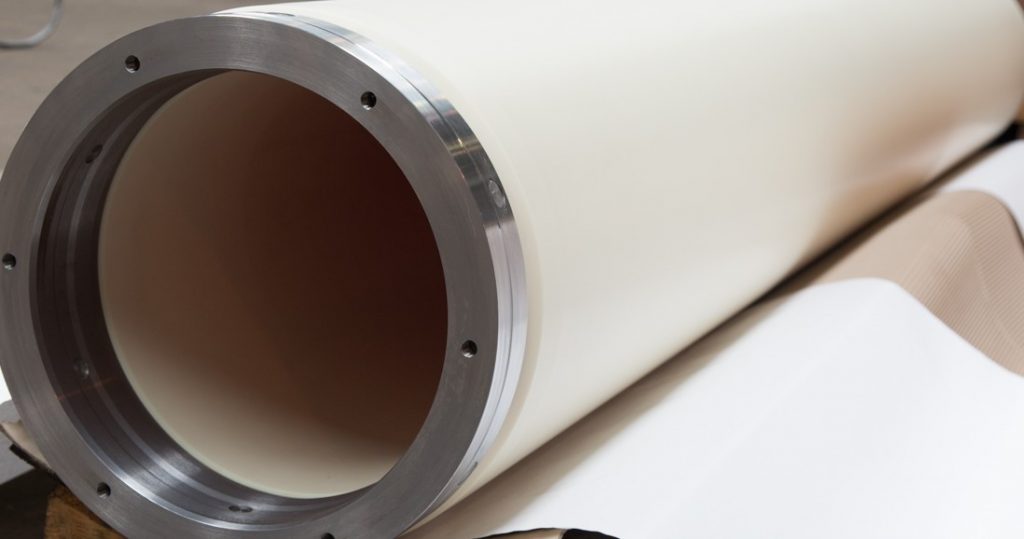

Cop cotton

Our high quality cotton bowls as exclusively specified by the world’s leading calender manufacturers

and used by the leading textile manufactures around the world.

Cop cotton is produced from 100% natural cotton, using a unique manufacture technique. We have a special method of making the bowls so that the cotton threads are oriented circumferentially around the bowl giving far greater strength to the cover and also a softer feel to the fabric.

Cop cotton has unrivalled performance in terms of resilience, heat resistance and lifetime of the fibres and the elastic characteristics of the binding system ensure the porous / open structure has a high degree of flexibility, elasticity and strength.

Applications:

- Textile and non-woven calendering

- Embossing

Key Features:

- High resilience and strength

- Excellent roll surface characteristics

- Achieves optimum fabric surface finish

- Excellent resistance to surface damage

Cotton bowls for:

- Universal Textile Calenders

- Schreiner Calenders

- Friction Calenders

- Embossing Calenders

- Bonding & Non-woven Calenders

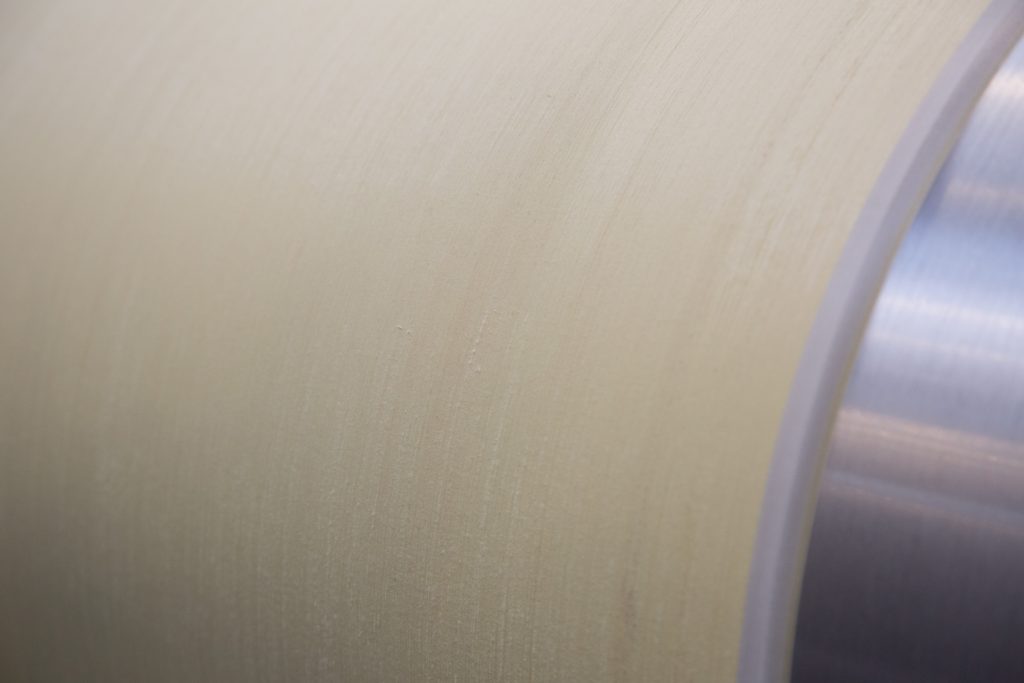

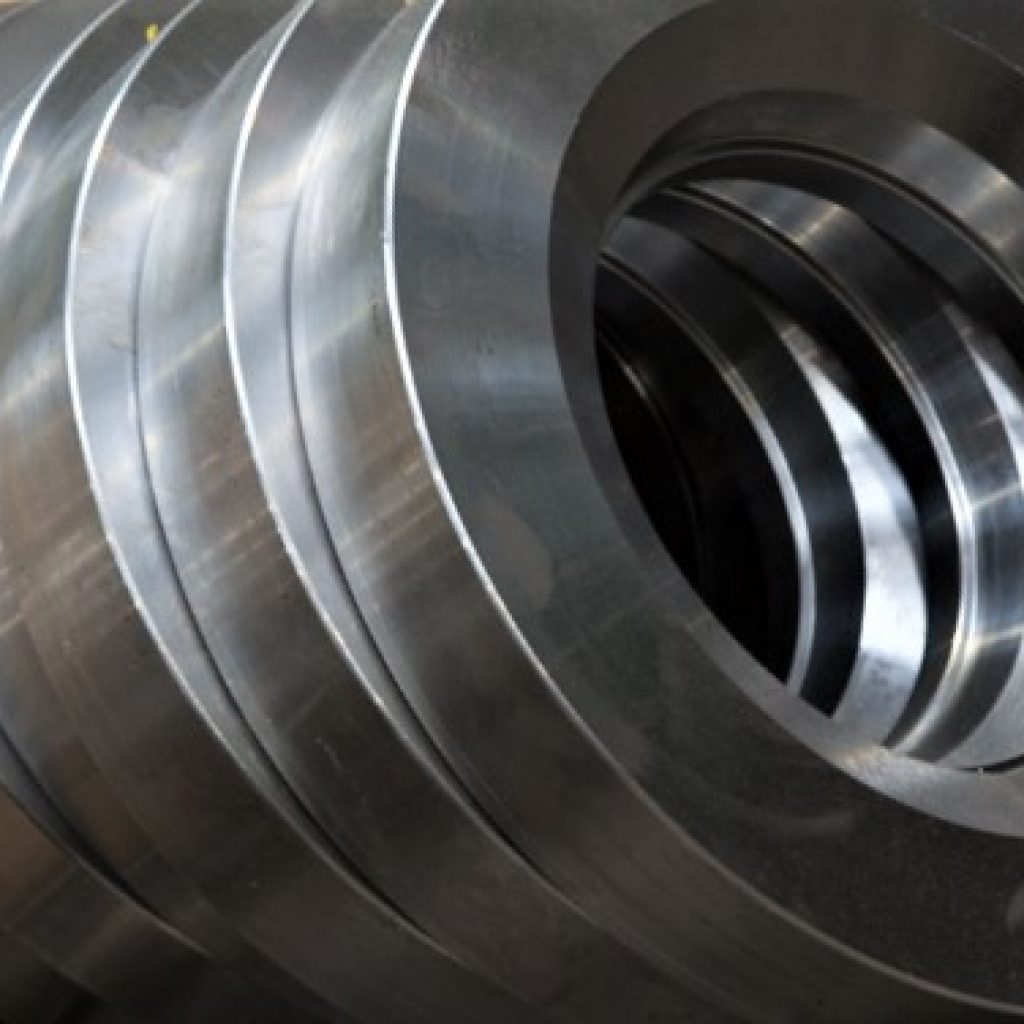

SYNCAST™ Polyamide calender rolls

Syncast™ Polyamide calender rolls from KWF are a state of the art solution for many calendering and embossing applications. Excellent resistance to surface damage ensures minimum maintenance and a very long service life.

Construction

Syncast™ is a uniquely elastic, thermoplastic polymer that has been specially developed for calender rolls. Syncast™ roll covers are centrifugally cast, guaranteeing perfect quality due to the exceptionally high revolving speed (2000rpm) utilised in the casting process. This high speed ‘spin casting’ ensures the expulsion of all air bubbles and impurities from the cover. Then natural atmospheric cooling of the cast polymer in the moulding process ensures the maximum reaction time, allowing longer molecules to form.

The optimised molecule length gives the Syncast™ calender roll cover its excellent elasticity and mark recovery, with minimum shape distortion. This results in excellent run-ability in the calender and maximum service life. Internal stresses are minimised in the Syncast™ calender roll cover as it is produced at temperatures below the melting point of the polymer.

Applications

- Calendering

- Woven and knitted natural fabrics

- Woven and knitted synthetic fabrics

- Non-wovens (thermobonding)

- Paper

Operational Benefits

- No ‘washing in’ required

- Highly resistant to surface marks, e.g. from sleeve edges, sewing seams, creases and knots etc.

- Most surface marks level out during operation

- Different material widths can be run without edge marking problems

- Resistant to most commonly used processing chemicals

- Syncast™ rolls can be re-machined several times and provide an excellent service life