Services

The KWF has an extensive machine park and highly skilled staff. Therefore, the company is able to offer a comprehensive all-around service for your rolls.

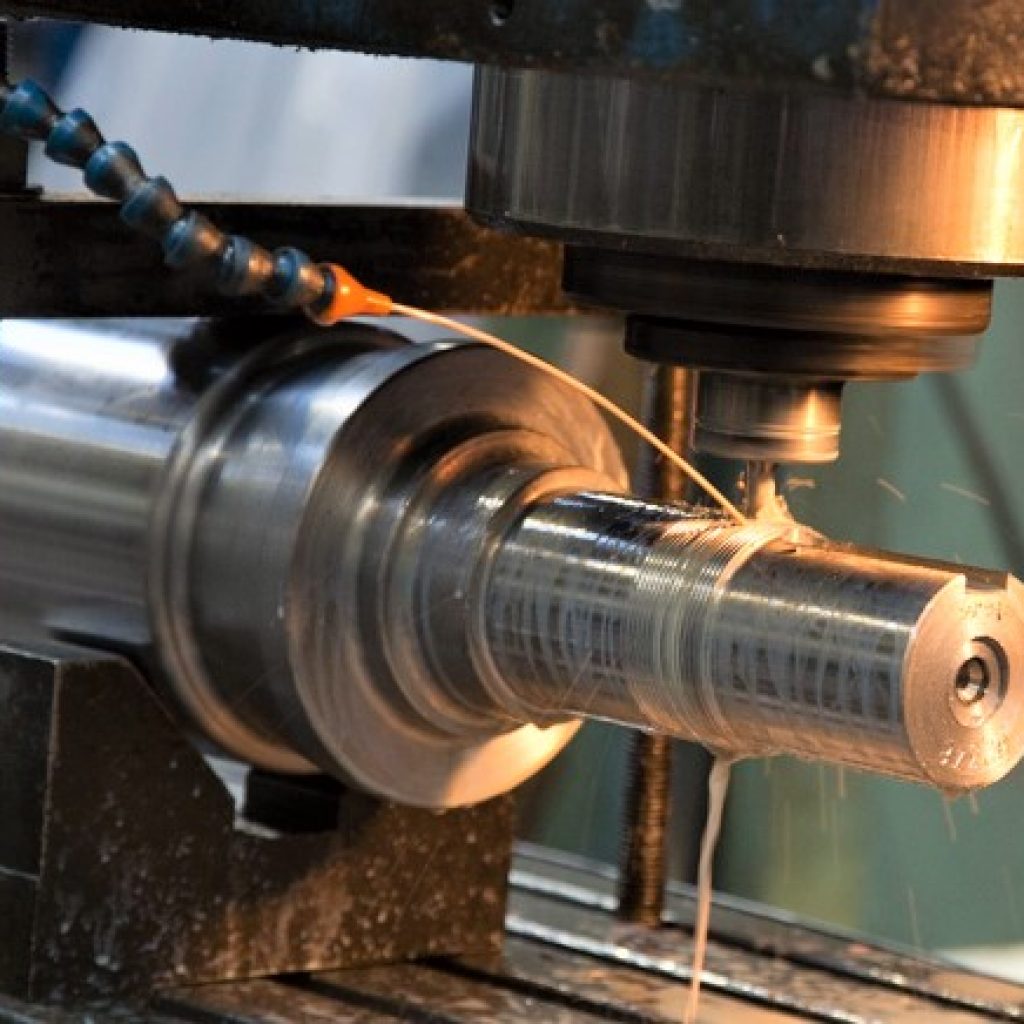

Manufacturing of new rolls

- Using CAD software to design bowls

- Designing safe locking mechanisms to ensure the cover, which is under enormous pressure, works well in the production environment and ensures workers safety.

- We only use the best base materials, from extra hardened steel to stainless-steel for new shafts. Our mechanical engineers and lathe operators, who each have over thirty years’ experience in fashioning new rolls, work to the precision of 1 / 100thof a mm.

- The company has an extensive archive of roll drawings dating back about 50 years. We also collaborate with all the main calendering machine specialists, like Andritz, Guarneri and Jagenberg.

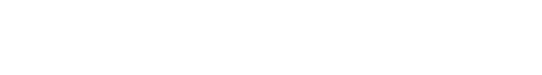

Roll & shaft re-conditioning

- Repairing journals, locking systems etc.

- Diverse shaft coatings are available to minimize rust build-up and to coat shaft for harsh production environments i.e. acidity, which helps protect and increase lifespan of bowl covers.