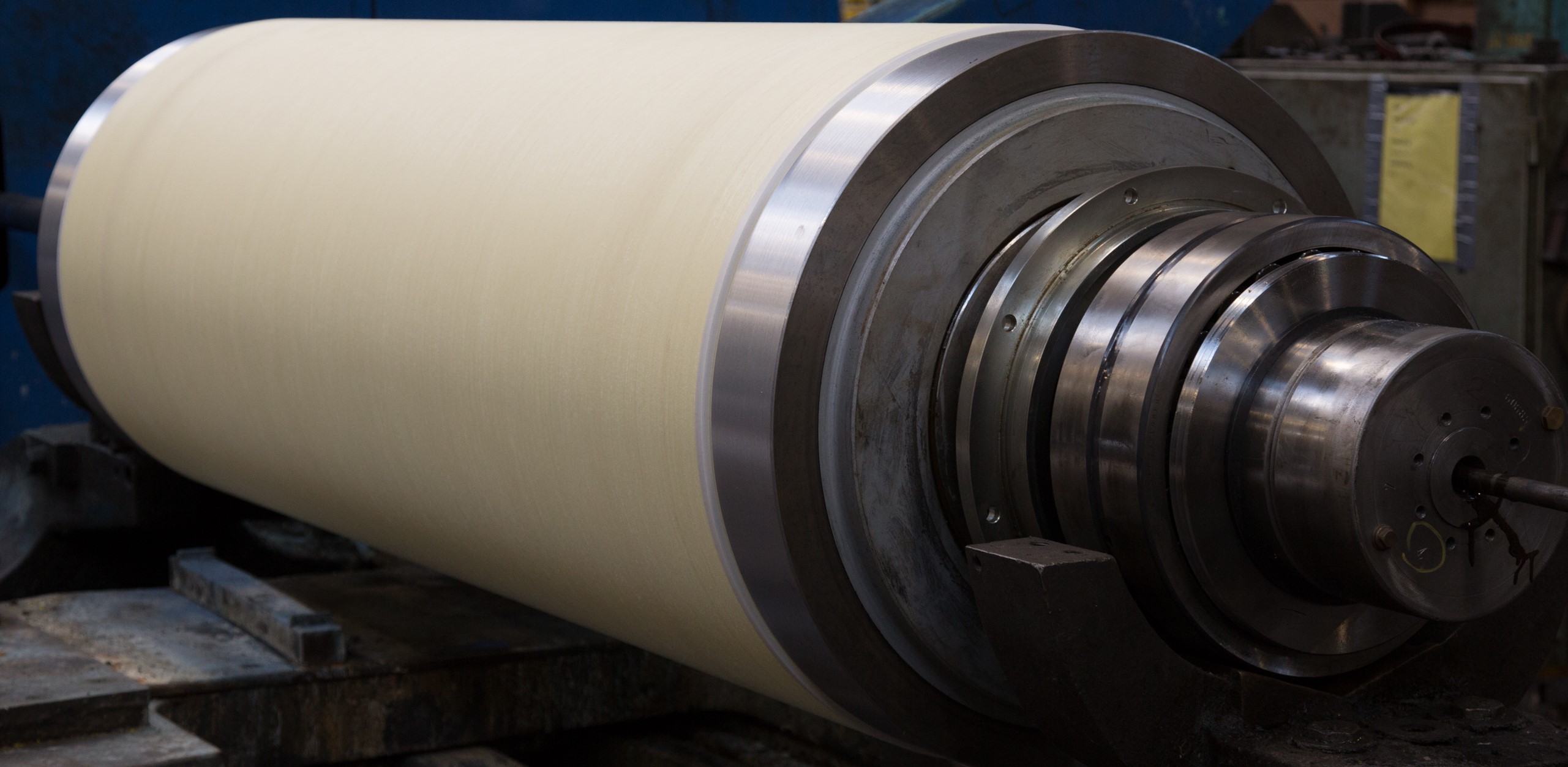

Embossing Rolls

Fibre filled backing rolls represent the best performing and most cost effective alternative

for the majority of embossing applications today.

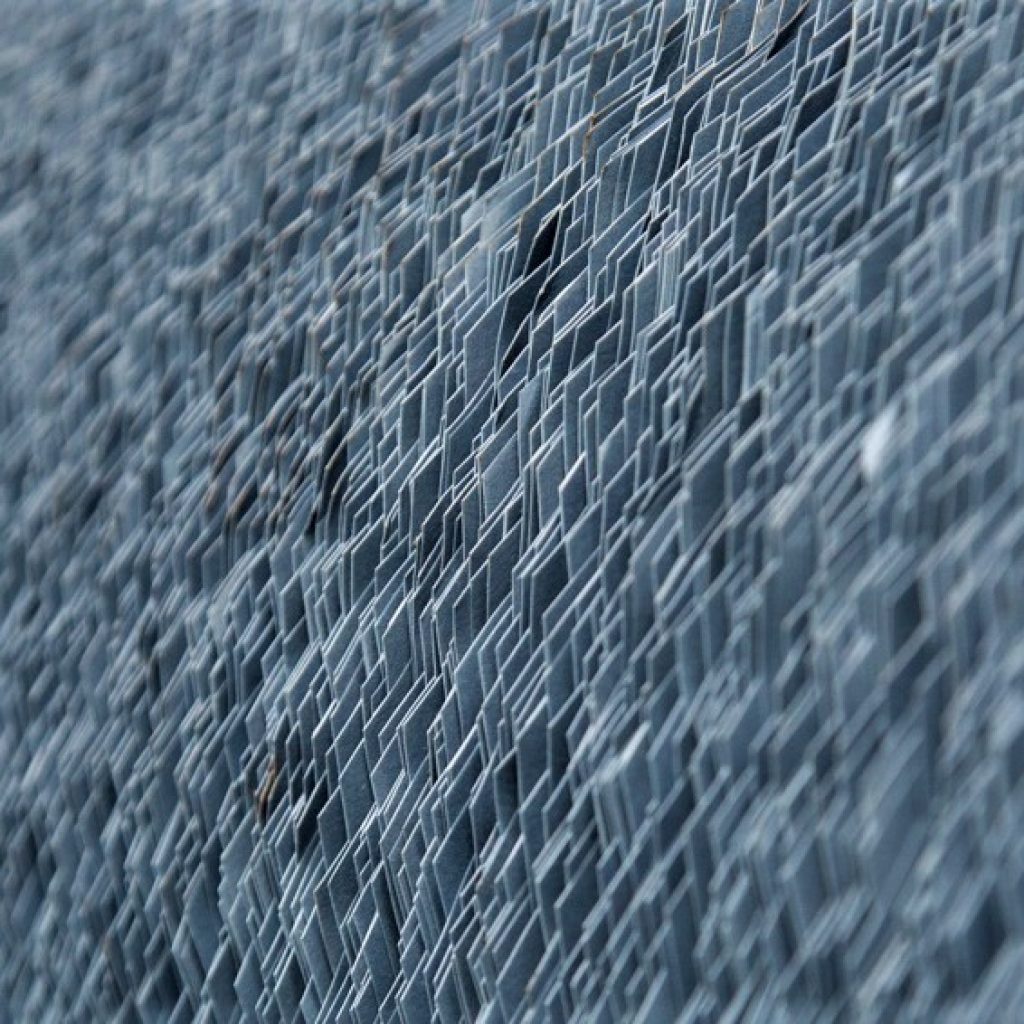

Woollen Paper

Bowl Properties related to Calendering Characteristics

- Cotton and wool paper-based cover of a pressed construction

- Wool content (10-45%) and hardness can be varied to suit

the application - Conforms to the engraved steel roll to give a precise emboss

- Suitable for fine or deep designs

- Geared and un-geared applications

Super Elastic™

- 100% woven cotton-based cover of a pressed construction

- Suitable for fine designs (under 1mm pattern depth)

- Greatly reduced run-in time

- Shallow patterns can be run over each other without the need for regrinding (ideal for Turret Embossers)

- Highly resilient – minor damage marks recover easily

- Less machining means longer roll life and reduced downtime

- Geared and un-geared applications

- Increased roll life and improved productivity over traditional woollen paper rolls

Syncast™

- Woven and knitted natural fabrics

- Woven and knitted synthetic fabrics

- Non-wovens

- Paper

- Vinyl / imitation leathers

- Aluminium foils

Operational benefits

- Excellent smoothing effect

- Excellent glazing effect when used in conjunction with a highly polished steel roll

- Excellent densification of calendered cloth

- Running stability enables higher and more homogenous lustre at higher speeds

- Syncast™ produces excellent lustre / feel / matt effects when used in combination with cotton rolls

| Syncast™ material | Polyamide PA6G: |

|---|---|

| Colour | Natural |

| Hardness | 87° +/-1 Shore D |

| Maximum surface temperature of heated steel roll | 200-220°C |

| Maximum surface temperature of SYNCAST™ roll | 130°C |

| Maximum linear pressure | 35o kN/m |