Simtex™

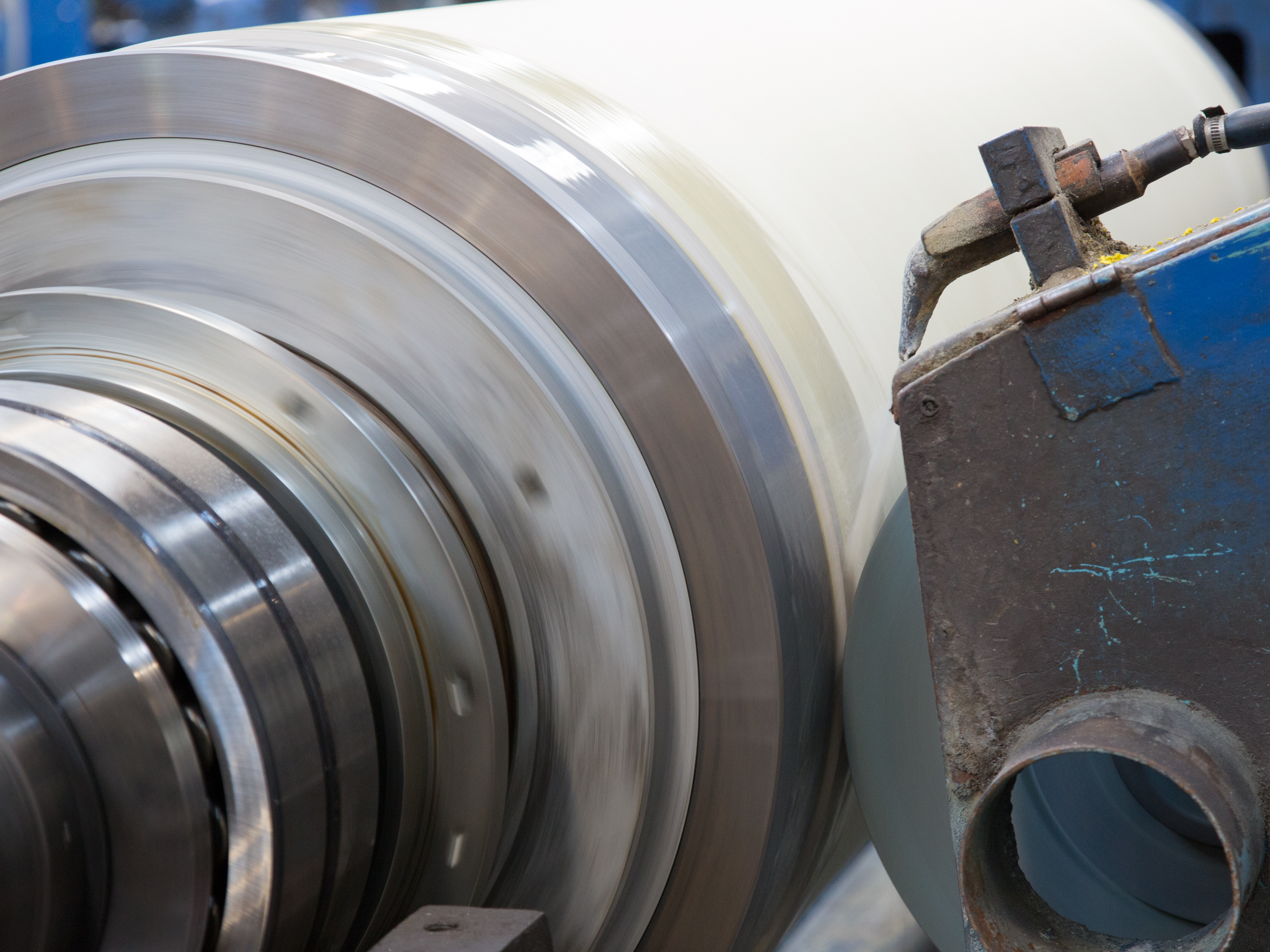

Simtex™ Embossing

High Performance embossing, game-changing performance

Our latest innovation, Simtex™, takes embossing to a new level of excellence. It uses a special formulation of specially selected synthetic fibres, prepared in a unique way, oriented circumferentially to coincide with the direction of material to be embossed. This approach ensures maximum ‘forged’ strength and therefore maximum definition.

One of the many advantages of using Simtex™ is that it is able to withstand 250c+ maximum surface temperature which allows for very high-speed embossing.

Why use Simtex™

- Regrind interval up to 1000 hours

- Shore D range 45-90

- Greater depth of material

- Longer life

- Minimal marking

- Suitable for fine designs (under 2mm pattern depth)

- Greatly reduced run-in time

- Highly resilient – minor damage marks recover easily

- Less machining means longer roll life and reduced downtime

- Geared and un-geared applications

- Increased roll life and improved productivity over traditional woollen paper rolls.

- SURFACE TEMPERATURE RESISTANCE 250˚C

- EMBOSSING SPEEDS 1000 M / MIN

Why upgrade to Simtex™

- Perfect definition can be obtained whether geared or ungeared

- No cooling system required

- Embossing speeds of up to 1000 m / min can be obtained

- Surface temperature resistance 250c+